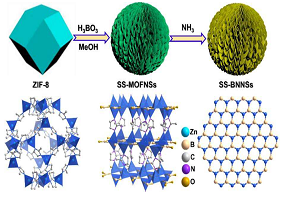

Boron nitride coating is a surface modification coating technology that applies boron nitride material. Boron nitride is a material with excellent physical and chemical properties and is widely used in high-temperature, high-hardness, and high-wear resistance fields.

By coating boron nitride materials on the surface of components, their performance can be effectively improved. The coating forms a hard and wear-resistant protective film, greatly enhancing the wear resistance, corrosion resistance, and high-temperature resistance of the components.

Advantages

I. High Hardness: Boron nitride coating has an extremely high hardness, reaching 2000 to 4000 HV, which is higher than the hardness of most metal materials.

II. Excellent wear resistance: Boron nitride coating has an extremely low coefficient of friction and excellent wear resistance, which can effectively reduce the degree of wear on parts and extend their service life.

III. High-Temperature Resistance: Boron nitride coating can maintain good performance stability at high temperatures and is less prone to deformation and peeling, making it suitable for high-temperature applications.

Applications

Boron nitride thermal spraying technology is widely used in various fields, here are a few examples of its applications:

A. Aerospace Industry: Aircraft engine components, aerospace bearings, turbine blades, etc.

B. Mechanical Manufacturing Industry: Mechanical Moving Parts, High-Speed Drill Cutting Tools, Bearings, etc.

C. Automotive Industry: key components such as automotive shock absorbers, engine pistons, and valves.

D. Ship Industry: marine bearings, hull coatings, etc.

The process of nitride boron coating and surface modification

Using physical vapor deposition (PVD) technology is a common method for nitride boron coating. This process involves evaporating the nitride boron material in a vacuum environment and depositing it on the surface of the component to form a dense coating.

The surface modification effect of the nitride boron coating is significant. First, the coating can fill in and smooth out the microscopic pits and cracks on the surface of the component, improving surface smoothness. Second, the coating can provide a protective film that blocks the corrosion of external media and slows down the oxidation rate of the component.

Conclusion

Boron nitride coating, as an advanced surface modification technology, has broad application prospects. It can improve the wear resistance, corrosion resistance, and high-temperature resistance of components, extending the service life of components. By using PVD technology to prepare boron nitride coatings, the surface quality of components can be effectively improved, and the density and adhesion of the coating can be improved. In the future, boron nitride coating technology will continue to develop and provide more reliable and high-quality coating materials for various industries.

-

The properties of Sn–Zn–Al–La fusible alloy for mitigation devices of solid propellant rocket motors

2025-06-09 -

Introduction of Niobium Tungsten alloy materials

2025-01-09 -

Boron nitride coating

2024-10-31 -

Scientists from the United States, Japan and South Korea have discovered five new isotopes

2024-10-10 -

Porous tantalum materials for surgical implants

2024-05-29 -

The application of niobium alloy and its coating for aerospace applications, and the development of other aerospace alloy materials are introduced

2024-05-13 -

Superconducting applications of Niobium

2024-05-07 -

Method for determination of niobium content in Ti45Nb alloy

2023-09-14 -

ISO 9001:2015 Certificate

2023-04-09 -

Niobium sheet with wide width barrier layer for superconducting wire

2022-12-29 -

Method of producing superconducting niobium pipe

2022-12-30