The method of determining niobium content in aviation material Ti45Nb alloy is to dissolve insoluble

test material with mixed acid of hydrochloric acid, nitric acid and hydrofluoric acid. In hydrofluoric

acid medium, titanium and aluminum ions are formed stable complex by hydrofluoric acid, niobium

and tetraphenylarsenic chloride hydrochloride are completely precipitated, and trace magnesium ions

are soluble precipitated. Tartaric acid is used to prevent the precipitation of hydrated oxides of high-priced

metal ions, after filtration, the magnesium precipitation is washed and dissolved, and finally the precipitation

is dried, ash, and burned into niobium pentaoxide, and the niobium content in the alloy is calculated

by weighing and calculating. The method of the invention has an alloy material with a mass fraction

of 40.0% ~ 50.0% that can determine the niobium content. It has the advantages of simple operation,

high accuracy, small error and good stability.

The method of ion exchange separation-gravimetric determination of niobium content is to separate

niobium from iron, nickel and other metal elements when the sample solution of hydrofluoric acid and

hydrochloric acid containing niobium is passed through a strong basic anion exchange column. After

adding boric acid to the niobium eluent, niobium is quantitatively precipitated with copper-iron reagent

in the hydrochloric acid medium, and then it is burned into niobium pentoxide, weighed and the mass

fraction of niobium is calculated. However, this method has the following problems: 1, this method is

only suitable for the determination of niobium content in alloy steel, superalloy and precision alloy; 2, the

ion exchange steps are complicated, practical is not very strong; 3. It is difficult to hide and separate high

titanium content.

The method for the determination of niobium content in Ti45Nb titanium alloy by tetraphenylarsenic

chloride hydrochloride gravimetric method is as follows: The insoluble test material was dissolved with

hydrochloric acid, nitric acid and hydrofluoric acid. In the hydrofluoric acid medium of 9mol/L ~ 12mol/L,

titanium and aluminum ions were formed into stable complexes by hydrofluoric acid, niobium and

tetraphenyl-arsenic-chloride hydrochloride were precipitated completely, and trace magnesium ions

formed soluble precipitates. Tartaric acid is used to prevent the precipitation of hydrated oxides of high-priced

metal ions. After filtration, the magnesium precipitation is washed and dissolved. The precipitation is dried,

ash, and burned into niobium pentoxide, weighed and calculated.To provide accurate chemical element

composition data for production control and scientific research, guide the research direction, and ensure

the quality of aviation products. The invention can determine the niobium content of 40.00% ~ 50.00%(m/m)

in Ti45Nb titanium alloy, and the detection error is ±0.15%.

-

The properties of Sn–Zn–Al–La fusible alloy for mitigation devices of solid propellant rocket motors

2025-06-09 -

Introduction of Niobium Tungsten alloy materials

2025-01-09 -

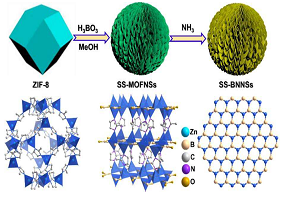

Boron nitride coating

2024-10-31 -

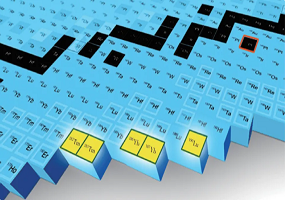

Scientists from the United States, Japan and South Korea have discovered five new isotopes

2024-10-10 -

Porous tantalum materials for surgical implants

2024-05-29 -

The application of niobium alloy and its coating for aerospace applications, and the development of other aerospace alloy materials are introduced

2024-05-13 -

Superconducting applications of Niobium

2024-05-07 -

Method for determination of niobium content in Ti45Nb alloy

2023-09-14 -

ISO 9001:2015 Certificate

2023-04-09 -

Niobium sheet with wide width barrier layer for superconducting wire

2022-12-29 -

Method of producing superconducting niobium pipe

2022-12-30