The porous tantalum material used in surgical implants is mainly used for the repair and reconstruction of surgical bone defects. Tantalum metal is used because tantalum is a refractory metal, which is non-toxic, harmless and has no side effects on human body, and has excellent biocompatibility. While porous tantalum material has good porosity and uniform distribution, which is consistent with the growth of human bone tissue. Therefore, as a bio-porous implant material, it is widely used in the surgical field.

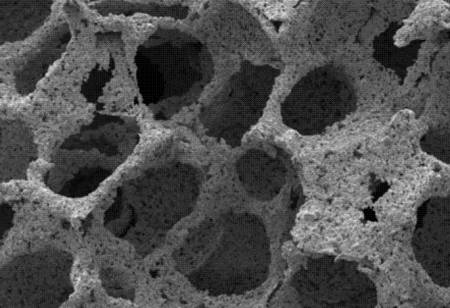

Porous tantalum material

When it comes to the field of medical surgery, naturally its quality requirements are extremely strict. We also attach great importance to the establishment of testing standards for porous tantalum materials used in surgical implants. The related properties and testing items of porous tantalum materials are specified.

Tantalum skeleton

The chemical composition of porous tantalum materials shall be carried out in accordance with the provisions of "Pure Tantalum for Metal Materials for Surgical Implants". In fact, the detection of tantalum chemical composition is mainly the determination of the main elements and trace elements. Therefore, the specific detection items of chemical composition mainly include carbon, oxygen, nitrogen, hydrogen, niobium, iron, titanium, tungsten, molybdenum, silicon, nickel and tantalum content. Of course, if the tantalum material does not meet the provisions of the standard, the manufacturer needs to provide what the specific chemical composition is, and it must pass the biological evaluation of the strict "Biological evaluation of medical devices in Part 1: Evaluation and testing in the Risk Management Process" standard.

Pore

Another important test index for porous tantalum materials used in surgical implants is porosity, which can be expressed as a percentage of density or a percentage of void volume. In addition to voidage, the internal connection of porous tantalum materials can be expressed by evaluating the gap intercept or the internal connection diameter between holes. Of course, the structure also needs to measure the microhole, macro hole size and allowable deviation. Since the product may be tailored, the shape of the porous tantalum material is rod-like. Or blocky? These need to be clarified.

Products of all shapes

In terms of physical properties, it is also clearly stipulated that the compression and bending properties of porous tantalum materials are mainly tested. Tantalum metal also needs to test grain size, tensile strength, non-proportional extension strength, elongation and other indicators. Of course, the specific testing items can be decided by the supply and demand sides through negotiation. The entrusted third-party testing institution must have the relevant medical testing qualification

The following table illustrates the mechanical properties of pure tantalum metal material for surgical implants using tantalum sheets and strips as an example, with reference to ISO 13782:2019.

Form | Status | Thickness/Diameter (d/mm) | Tensile Strength (Rm/MPa) | Specify the non-proportional elongation strength (Rp0.2/MPa) | Percentage elongation after fracture A/(%) |

Sheet and strip | Cold machining | ≥0.13 | ≥520 | ≥345 | ≥2 |

-

The properties of Sn–Zn–Al–La fusible alloy for mitigation devices of solid propellant rocket motors

2025-06-09 -

Introduction of Niobium Tungsten alloy materials

2025-01-09 -

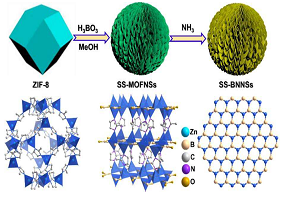

Boron nitride coating

2024-10-31 -

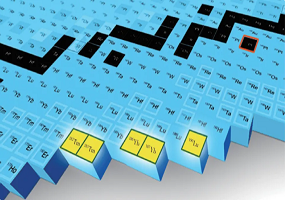

Scientists from the United States, Japan and South Korea have discovered five new isotopes

2024-10-10 -

Porous tantalum materials for surgical implants

2024-05-29 -

The application of niobium alloy and its coating for aerospace applications, and the development of other aerospace alloy materials are introduced

2024-05-13 -

Superconducting applications of Niobium

2024-05-07 -

Method for determination of niobium content in Ti45Nb alloy

2023-09-14 -

ISO 9001:2015 Certificate

2023-04-09 -

Niobium sheet with wide width barrier layer for superconducting wire

2022-12-29 -

Method of producing superconducting niobium pipe

2022-12-30