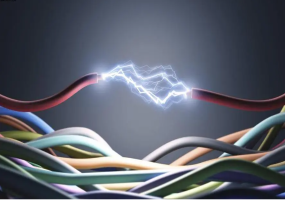

When the temperature drops close to absolute zero, some substance undergo a sudden chemical

change and become a "superconductor" with almost no resistance. The temperature at which

matter begins to take on this strange "superconducting" property is called the critical temperature.

Needless to say, the critical temperature of various substances is not the same.

You know, ultra-low temperatures are not easy to get, and people pay a huge price for it.

The closer we get to absolute zero, the greater thecost. Therefore, our requirement for

superconducting materials is, of course, the higher the critical temperature, the better.

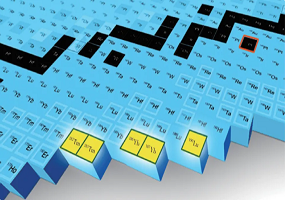

There are many elements with superconducting properties, among which niobium has the

highest critical temperature. Alloys made of niobium, with critical temperatures as high as

18.5-21 degrees absolute, are currently the most important superconducting materials.

A large portion of the world's niobium is used in the production of nickel, chromium

and iron-based superalloys in pure metallic form or in the form of high purity ferric niobium

and niobium nickel alloys. These alloys are used in jet engines, gas turbine engines,

rocket components, turbochargers and heat-resistant combustion devices. Niobium

forms a γ "phase in the grain structure of the superalloy. These alloys generally

contain up to 6.5% niobium.

Niobium C-103 Alloy is a niobium alloy containing 89% niobium,

10% hafnium and 1% titanium, which can be used in liquid rocket propulsion nozzles, such as

the main engine of the Apollo lunar module. The Apollo service module used another

niobium alloy. Since niobium begins to oxidize above 400°C, a protective coating

must be applied to its surface in order to prevent it from becoming brittle.

Tag: High RRR Niobium material for SCRF C-103 Niobium Hafnium alloy

-

The properties of Sn–Zn–Al–La fusible alloy for mitigation devices of solid propellant rocket motors

2025-06-09 -

Introduction of Niobium Tungsten alloy materials

2025-01-09 -

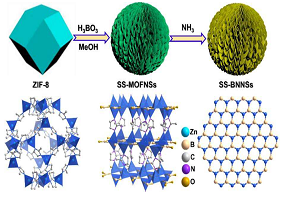

Boron nitride coating

2024-10-31 -

Scientists from the United States, Japan and South Korea have discovered five new isotopes

2024-10-10 -

Porous tantalum materials for surgical implants

2024-05-29 -

The application of niobium alloy and its coating for aerospace applications, and the development of other aerospace alloy materials are introduced

2024-05-13 -

Superconducting applications of Niobium

2024-05-07 -

Method for determination of niobium content in Ti45Nb alloy

2023-09-14 -

ISO 9001:2015 Certificate

2023-04-09 -

Niobium sheet with wide width barrier layer for superconducting wire

2022-12-29 -

Method of producing superconducting niobium pipe

2022-12-30