Product description

For dimensional stability and improved handling with ease of die cutting and laminating.

The high adhesion adhesive provides excellent adhesion to a variety of surfaces.

Good resistance to temperature,conductive and shielding properties

Application areas

For PAD, PDP, LCD monitors, notebook electronic glue, copiers, mobile phones, cable assemblies, communications equipment and other parts of the electromagnetic shielding.

Item | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD |

009030 | 018038 | 035045 | 018050 | 025060 | 035050 | 035070 | 050085 | 050090 | 045100 | 075120 | 100150 | |

Total thickness (mm) | 0.03 | 0.038 | 0.045 | 0.05 | 0.06 | 0.05 | 0.07 | 0.085 | 0.090 | 0.10 | 0.12 | 0.15 |

Size (width×length) 600*50 310*50 390*50M;

REMARK: Substrate T0.018, width 310*length50M

Substrate thickness 0.009 0.018 0.035 0.018 0.025 0.035 0.035 0.050 0.050 0.045 0.075 0.100

Adhesive Acrylic

colour Copper colour

Tube core 3.0” (76.0) /green

Release paper/film White paper (white 0.15)

Typical Physical Properties and Performance Characteristics

Note: the following technical information and data are subject to international or industry standard test results for customer selection or acceptance of reference.

Item HMCD HMCD HMCD HMCD HMCD | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD | HMCD |

009030 018038 035045 018050 025060 | 035050 | 035070 | 050085 | 050090 | 045100 | 075120 | 100150 |

180°C peeling force 304SS mirror sheet (Kgf/25.4*25.4) ≥0.80 ≥1.00 ≥1.00 ≥1.20 ≥1.20 standard:ASTM‐D3330 |

≥0.80 |

≥1.20 |

≥1.20 |

≥1.20 |

≥1.20 |

≥1.50 |

≥1.50 |

180°C peeling force

Aluminum sheet (Kgf /1inch 72H RT)

Standard: ASTM‐D3330

≥0.80 ≥1.00 ≥1.00 ≥1.20 ≥1.20 ≥0.80 ≥1.20 ≥1.20 ≥1.20 ≥1.20 ≥1.50 ≥1.50

Viscous force# ≥1# ≥1# ≥1# ≥1# ≥2# ≥1# ≥2# ≥2# ≥2# ≥2# ≥2# ≥2#

(1 inch)Heat strength

ASTM D3654 1000grams at 72 ˚ F (22℃)

4H 4H 8H 12H 12H 4H 12H 12H 12H 12H 24H 24H

Temperature resistance Long Term (days, weeks) 80℃

Short Term (minutes, hours) 120℃

Surface resistance level≤100m Ω (conductive adhesive) , Vertical≤100 mΩ

Base heat conductivity 400 W/mk

Standard: ASTM D5470

UV Resistance Moderate

Shelf life Form 12 months from date of manufacturing when stored in original cartons

at 10‐25 ℃ and 30‐70% relative humidity.

Instructions

The User is responsible for determining whether this EDAL's product is suitable for a particular purpose and method of usage for the user. Keep in mind that many factors can affect the using

and performance of a product, including the material with which it is bonding, and the surface

condition of the material with which it is bonding; As well as the conditions of using, time and environment of the materials fitted with it.

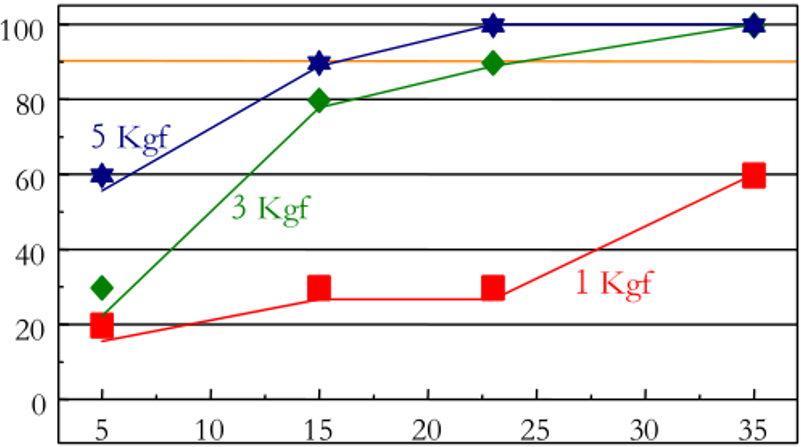

Relationship between temperature, pressure and wetted area

Soakage rate (%)

Temperature°C

Conclusion: in order to obtain more than 90% of sufficient infiltration, the required operating temperature above 15 degrees Celsius and more than 5 kg of pressure.

Surface treatment:

For optimal adhesion, the surface must be clean, dry and flat.Clean the oil and dust on

the adhesive surface with solvents such as isopropyl alcohol, gasoline or toluene. The

adhesive surface belonging to rubber or resin must be coated with primer (treatment agent).

Note: Be sure to do surface cleaning before bonding! Please read and follow the company's precautions carefully when using solvents for treatment.

Parts installation

Test assemble the part, check the position, then peel the Release Paper and install

the part. Remember do not to touch the adhesive surface.

If the bonding surface is clean, the parts can be stripped and re-bonded.

(not suitable for coated surfaces).

The parts should be installed in the correct position. Incorrect position may cause the tape to fall off.

The parts and bonding surface should be heated with a heating machine if the temperature is less than 15 °C (the best range is druing 21- 38°C).

Pressure

Apply a force of 2-3kg to the pasted area while attaching the bonded material.

If there is residual air between the tape and the adhesive surface that causes

the adhesive force to decrease, apply sufficient pressure.