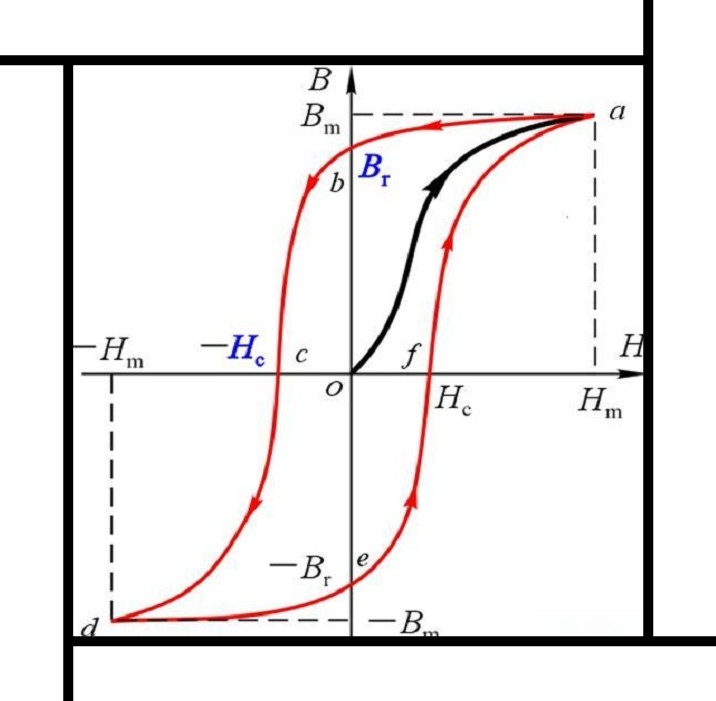

Magnetic materials with low coercive force, also known as high-permeability materials, are used in the power industry to make the cores of electrical equipment such as motors and transformers. In the electronics industry, they are used to manufacture various magnetic components and are widely applied in television, radio and communication fields. These materials have high saturation flux density, high permeability, narrow and long hysteresis loops with small areas, low hysteresis loss, low residual magnetism and low coercive force. When used in alternating current situations, they require low eddy current loss and hysteresis loss. Commonly used materials include pure iron, low-carbon steel, silicon steel sheets, permalloy and ferrite.

(a) Pure iron and low-carbon steel: They have high magnetic permeability and good processing performance. However, they have large eddy current losses and are only suitable for DC cores.

(b) Silicon steel sheets and silicon steel strips: They have high resistivity and low eddy current losses. However, they are brittle and have poor processing performance. They are used in sheet form by stacking or in a ring shape. Insulating varnish is applied between the sheets or an oxide layer is formed to reduce eddy current losses.

(c) Permalloy: A general term for iron-nickel alloys, it has a very high magnetic permeability. It is used in precision instruments, recording heads, or in situations where a small volume is required.

(d) Ferrite: With Fe2O3 as the main component, it is mixed with Mn-Zn or Ni-Zn, etc., and pressed into manganese-zinc ferrite or nickel-zinc ferrite by powder metallurgy. It has high resistivity and low high-frequency losses. The former is used below 1 MHz, and the latter is used at microwave frequencies. The higher the working frequency, the lower the magnetic permeability. Ferrite is a ferrimagnetic material and has a lower magnetic permeability than ferromagnetic materials.

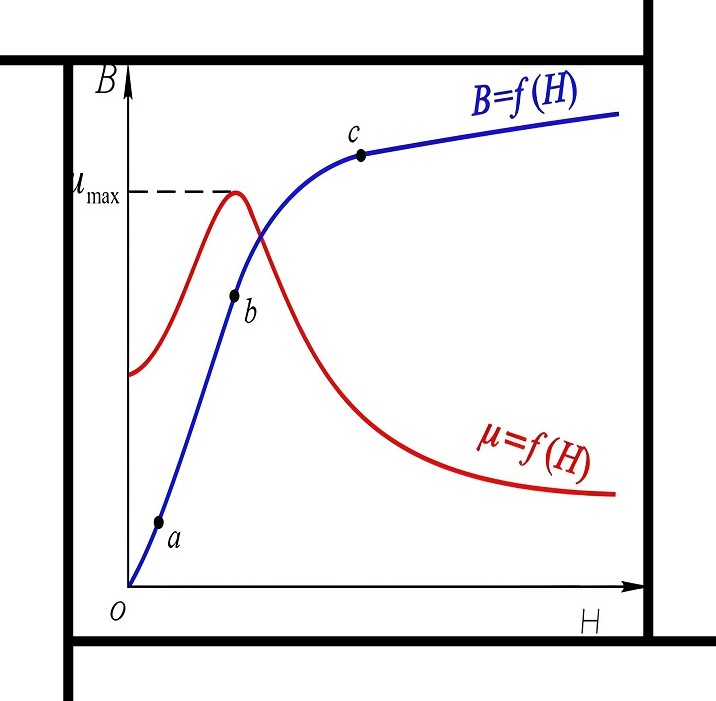

The main characteristics of soft magnetic materials

When magnetization occurs with Hc not exceeding 1000 A/m, such materials are called soft magnetic materials. Typical soft magnetic materials can achieve the maximum magnetic induction intensity with the smallest external magnetic field.

Soft magnetic materials are magnetic materials with low coercivity and high magnetic permeability. They are easy to magnetize and demagnetize, and are widely used in electrical and electronic equipment. The most commonly used soft magnetic materials are iron-silicon alloys (silicon steel sheets) and various soft magnetic ferrites, etc.

Classification of Applications

Soft magnetic materials can be classified into three major categories

Metallic soft magnetic materials

Ferrite soft magnetic materials

Magnetic media

Among them, metallic soft magnetic materials are further divided into four types: electromagnetic pure iron, silicon steel sheets, iron-nickel alloys, and iron-aluminum alloys.

The types, characteristics and application range

| Type | Main characteristics | Application range |

Electromagnetic pure iron | The carbon content is less than 0.04%, the saturation magnetic induction strength is large, and the cold workability is good.However, the resistivity is small, the iron loss is large, and there is magnetic aging phenomenon. | Generally used for DC magnetic fields. |

Silicon steel sheet | Compared with electrical pure iron, the resistivity increases, the iron loss decreases, and the magnetic aging is basically eliminated.But the thermal conductivity decreases, the hardness increases, and the brittleness increases. | Motor, transformer, relay, transformer, switch and other products iron core |

| Iron-nickel alloy | Compared with other soft magnetic materials, in the weak magnetic field, the permeability is large, coercivity is small, but it is more sensitive to stress. | Devices operating in weak magnetic fields with frequencies below 1MHz |

| Ferroaluminum alloy | Compared with iron-nickel alloy, the resistivity is large, the weight is light, but the permeability is small. With the increase of aluminumcontent, the hardness and brittleness increase and the plasticity becomes worse. | Devices operating in weak and strong magnetic fields |

Ferrite soft magnetic | It is a sintered body formed by metal oxidation through ceramic process, with great resistivi-ty and minimal eddy current loss. The satura-tion magnetic induction intensity is small and the temperature stability is poor. | High frequency or higher frequency range, the power of magnetic components is not too large |

Magnetic medium | It is made of powder of metal soft magnetic material glued by insulating material. It has low eddy current loss, good stability and higher price. | Devices operating under weak magnetic fields in the low or high frequency range |

Soft magnetic materials will develop along the direction of high Bs, high m, high Tc, low Pc, low Hc and high frequency, miniaturization, and thin shape to meet the increasing trend of thin film and miniaturization of magnetic components, and even integration.

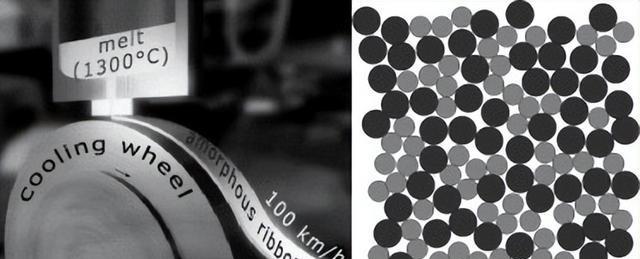

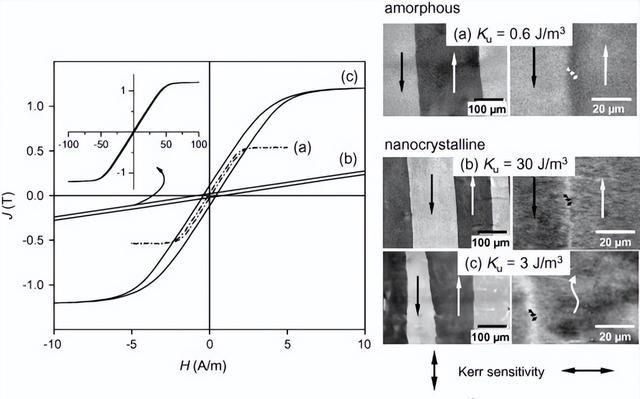

In the development process of soft magnetic materials, the early 20th century was the world of metal soft magnetic, and the middle period was the golden age of soft magnetic ferrite. Since the successful development of amorphous soft magnetic alloys in the middle and late period, and then the successful development of nanocrystalline soft magnetic materials, many nanocrystalline soft magnetic materials with high initial permeability and low coercivity have been found, and many soft magnetic materials with nanoparticle structure with excellent high frequency characteristics have been developed in recent years. The rise of nano-structured metallic magnetic materials has become a strong competitor to soft magnetic ferrites.