Application of tantalum metal

In the production of inorganic acid equipment, tantalum can be used to replace stainless steel, the life is more than ten times longer than stainless steel; In the chemical, electronic, electrical and atomic energy industries, it can replace the precious metal platinum, greatly reducing costs; As an important element in refining super-strength steel, corrosion-resistant steel and heat-resistant alloy steel, it can be used as a special material required for space technology such as rockets, spacecraft and jet aircraft. Tantalum and 7.5% tungsten made of non-magnetic alloy, in the red heat conditions' can remain elastic, widely used in electrical industry, electronic tube industry; Tantalum strips are also used in rectifiers; Used in the manufacture of surgical tools, artificial fiber drawing die, etc., is a substitute for platinum; Tantalum carbide has a very strong hardness and a very high melting point, at high temperature conditions and diamond, with the cutting knife made of it, can cut many hard alloys at high speed; The drill made of it can replace the hardest alloy or diamond drill bit;

Biocompatibility is good for repairing and sealing fractures and defects of broken skulls and limbs of human body; Tantalum filaments can be used as surgical sutures to replace tendons and nerve fibers. Tantalum plates can be used as artificial tantalum ears.

Product form and corresponding market share of tantalum material in 2023

Product form and application field | Market share |

Capacitor grade high specific volume tantalum powder, mainly used in mobile phones, portable computers, communication stations, automotive electronic components, digital cameras | 49% |

Corrosion-resistant tantalum products for chemical equipment | 14% |

Tantalum material with high melting point and low thermal expansion for super alloys | 9% |

TaC material for cutting tools | 13% |

Other | 15% |

- Tantalum for electronic industry 60%~65% of tantalum is used in tantalum capacitors; Connection materials for microprocessors and digital signal processors.

- Tantalum aero engine blades, seals and nozzles for superalloys.

- Tantalum armor-breaking shells for weapon systems, explosive-formed ammunition type covers.

- Coating material Coating material for tungsten solid targets in tantalum high energy accelerators.

Impurity contents of tantalum ingots under different preparation methods

SN | Manufacturing technique | Impurity element contents(×10-6) | ||||||

Si | Fe | Mo | Ni | Cr | Al | Nb | ||

#1 | Electron-beam smelting | 20 | 19 | 10 | 3 | 5 | - | 5 |

#2 | Powder metallurgy | 36 | 360 | 21 | 10 | 12 | 78 | 36 |

Hardness value of pure tantalum after 90% cold deformation by different annealing processes

SN | Different annealing conditions | ||||||

Cold deformation | 800℃ /60min | 800℃ /60min | 900℃ /60min | 1000℃ /60min | 1100℃ /60min | 1200℃ /60min | |

#1 | 201 | 175 | 125 | 83.5 | 79.2 | ||

#2 | 272 | 271 | 257 | 243 | 224 | 195 | 130 |

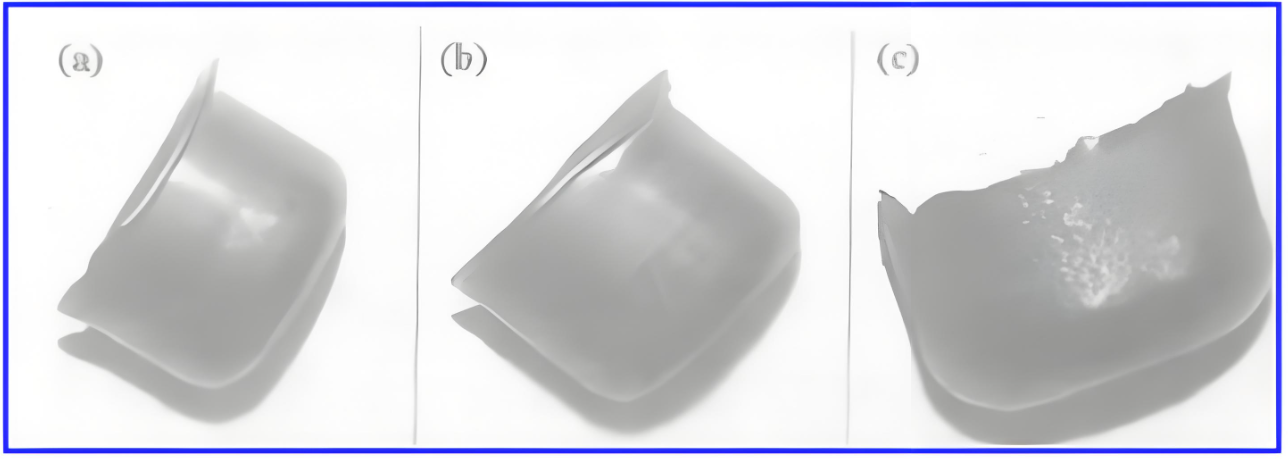

#1 Macroscopic morphology of deep pressed tantalum shell

(a) 90% deformation after 850℃, 60 min annealing

(b) 90% deformation after 900℃, 10 min annealing

(c) Annealing at 1150℃ for 60 min

The main reason for the poor surface quality of tantalum sheet deep stamping products is the coarse grain.

Mechanical properties of tantalum plates at different angles for Armor busting ammo type hood

Angle direction/( °) | Mechanical properties | |

δ% | σb /MPa | |

0 | 33 | 350 |

15 | 31 | 300 |

30 | 30 | 312 |

45 | 41 | 295 |

60 | 38 | 300 |

75 | 33 | 370 |

90 | 31 | 380 |

In the rolling process of tantalum plate, no matter what kind of cross rolling is adopted, it is inevitable to produce a strong texture inside the material.

The formation of these textures causes great changes in the strength and elongation of tantalum plates in different hair directions.

In the direction of 45°, the tensile strength of tantalum plate is the weakest and the elongation reaches the maximum.

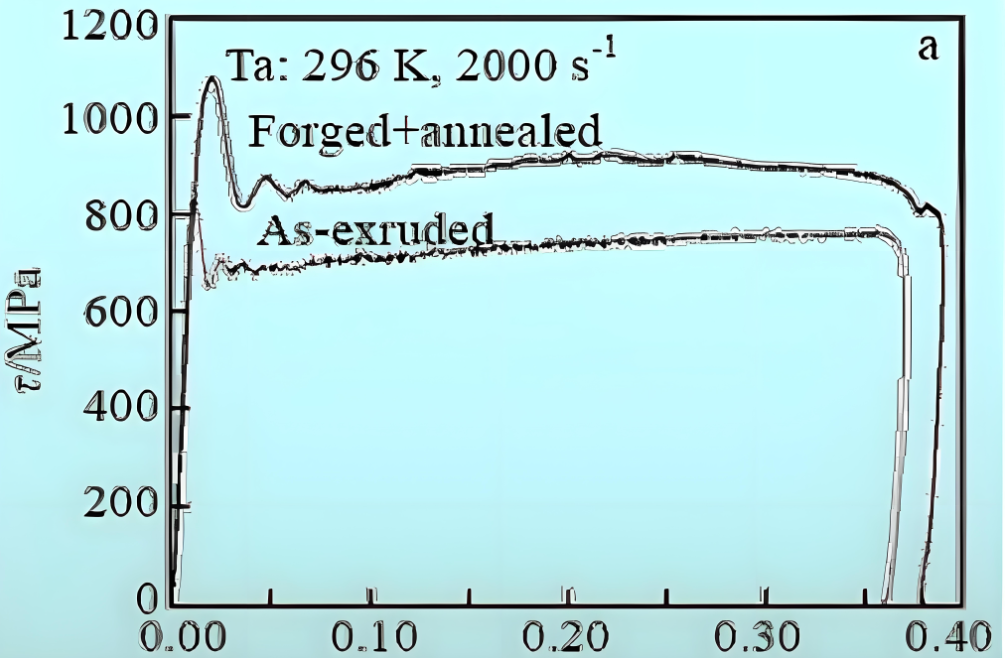

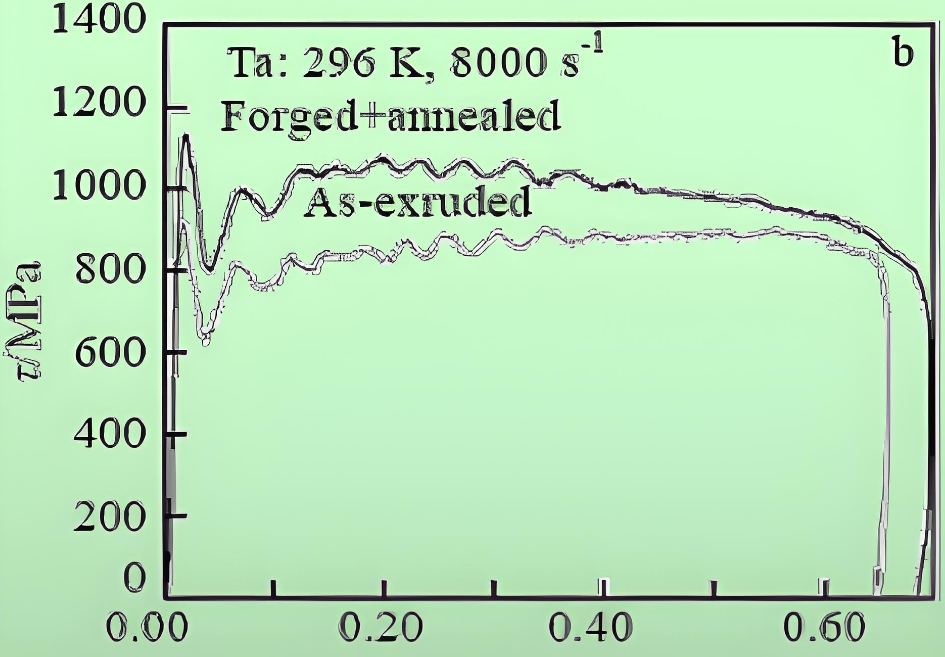

Properties of forged tantalum

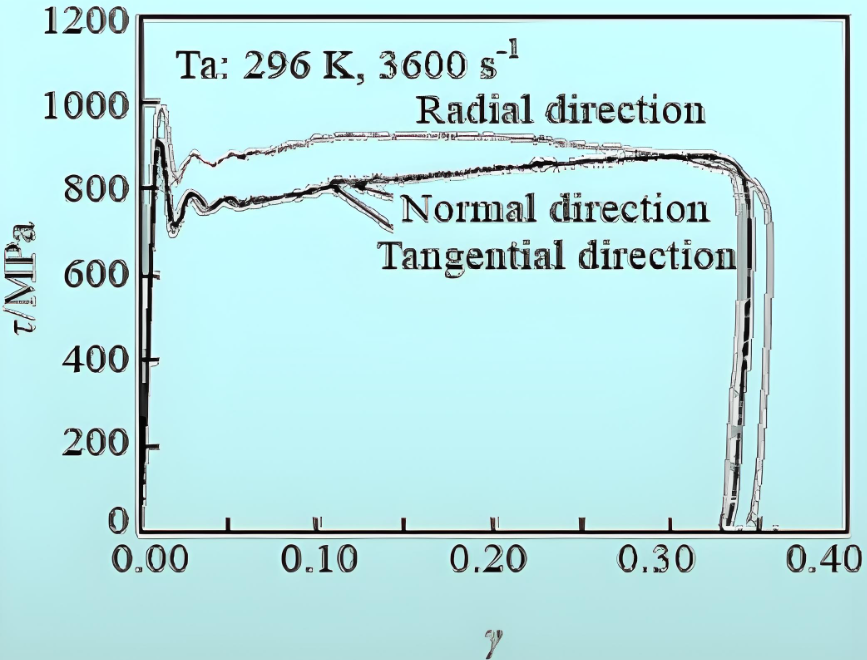

Initially extruded tantalum (as-extruded tantalum) and secondary forging and 1523K, 2h vacuum annealed

tantalum(forged+annealed) Real stress-strain curve at 296K temperature and different strain rates

The flow stress of tantalum after secondary forging is obviously increased by about 200MPa.

Flow stress curves of initially extruded tantalum rods at different orientations

The pure tantalum material shows anisotropy at the center of the disc, and becomes weaker with distance from the center of the disc.

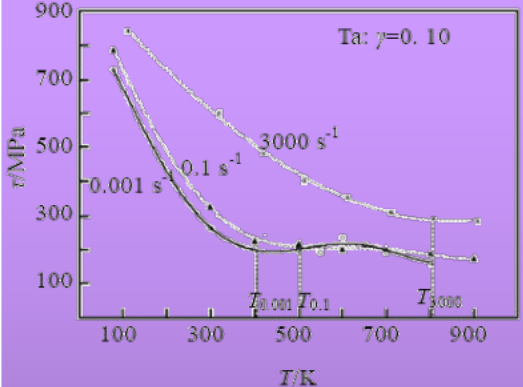

Flow stress of tantalum at different strain rates and temperatures

(a) The flow stress of tantalum is dependent on strain rate and temperature; (b) Below a certain temperature value,

the flow stress increases sharply with the decrease of temperature, reflecting the heat-activated dislocation slip

mechanism of plastic flow; (c) In a high temperature region, the flow stress is not sensitive totemperature, and the flow

stress peaks with increasing temperature. With the increase of strain rate,this high temperature region moves to a higher

temperature region, or even disappears, which is called dynamic strain aging.

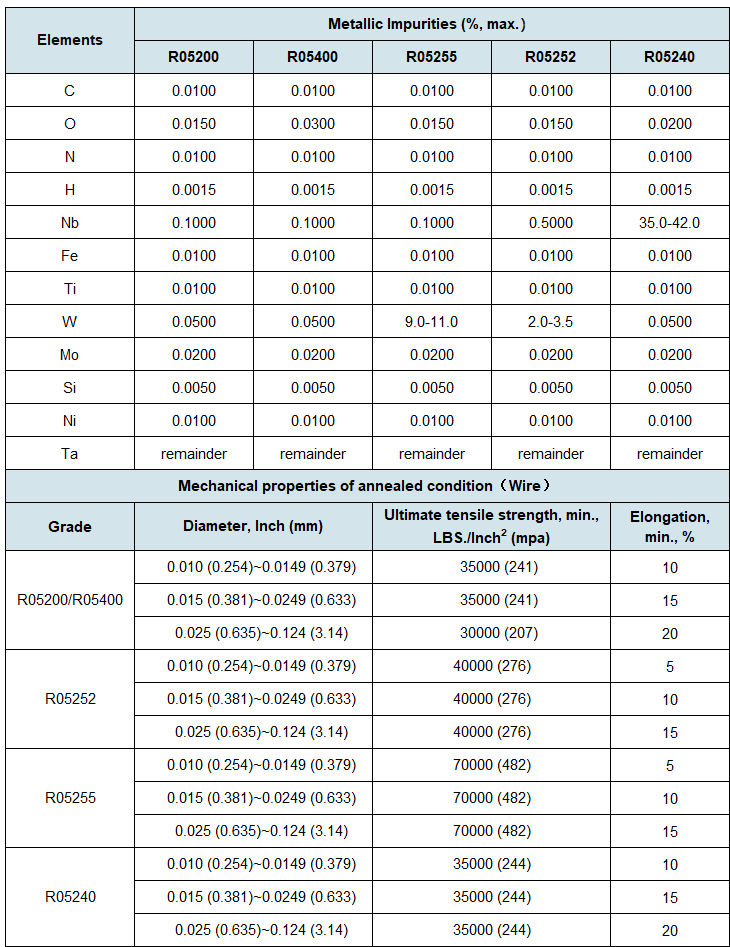

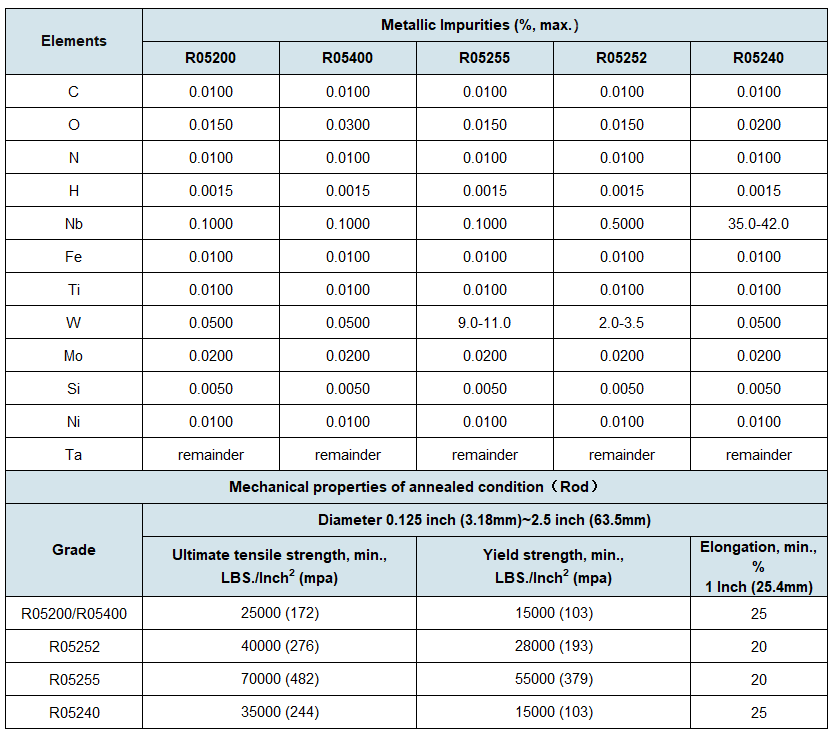

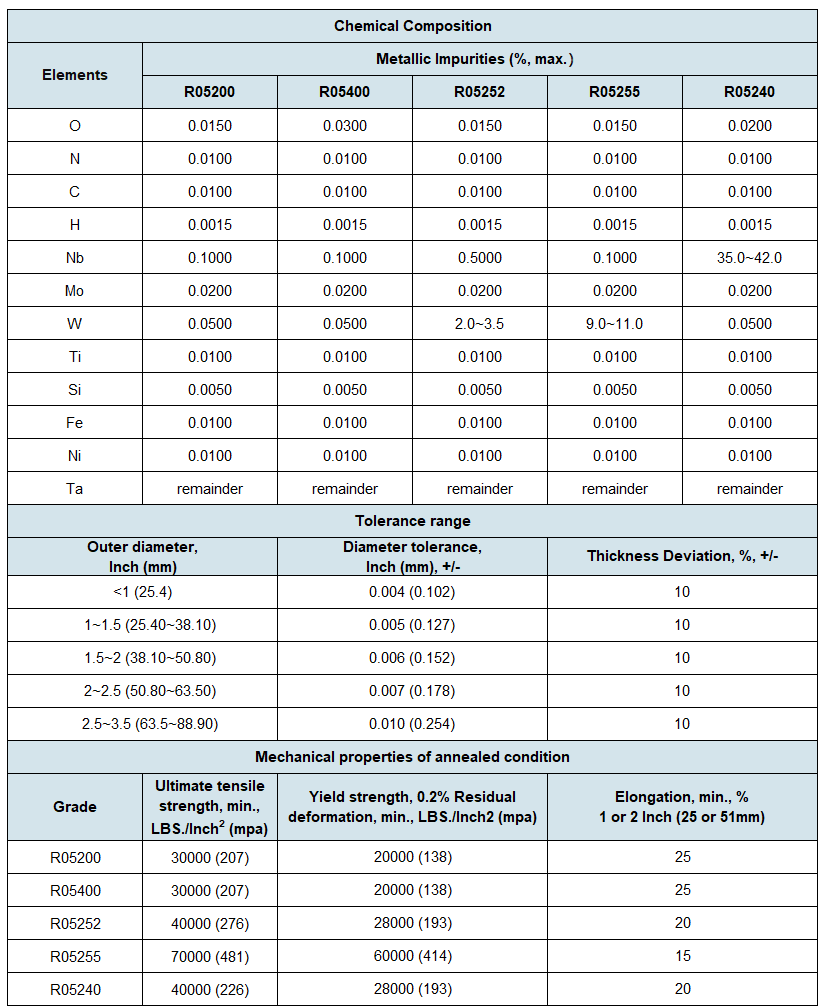

Tantalum rod ASTM B365(Physical and chemical properties)

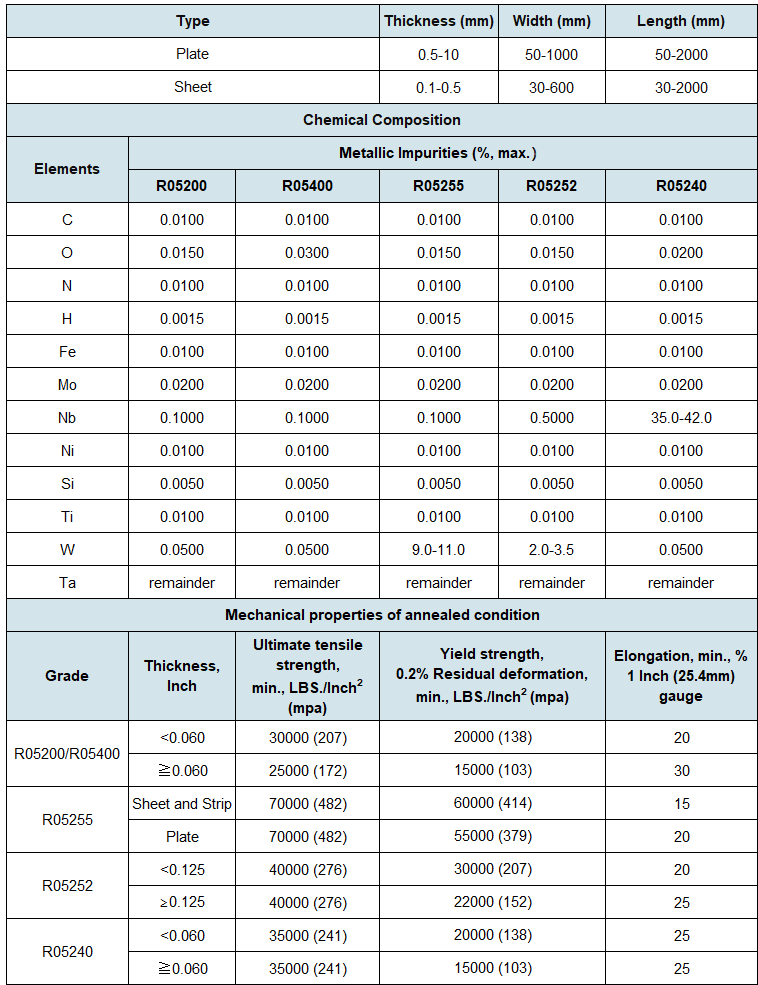

Tantalum sheet ASTM B708,ASTM7849,ASTM F560 (Physical and chemical properties)

Tantalum tube ASTM B521 (Physical and chemical properties)

Tantalum wire ASTM B365(Physical and chemical properties)