Niobium C-103 Application

Niobium alloy C-103 is an excellent material for liquid rocket thruster nozzles, lightweight propulsion systems and rocket engine thrust chamber in aerospace industry. Niobium alloy

C-103 is also used in the manufacture of turbopump and high-temperature jet engine parts.

It is obvious that niobium alloy C-103 is an ideal material in space engineering fabrication.

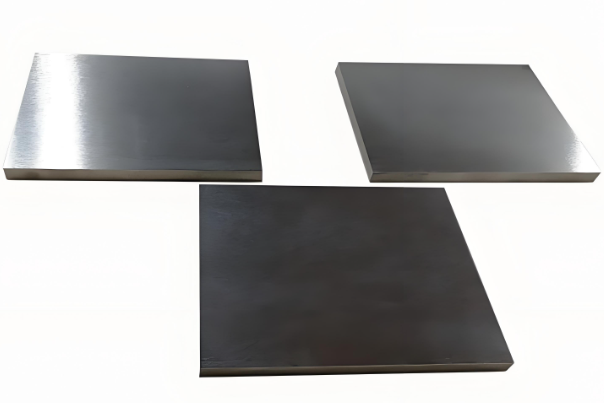

Niobium C-103 Fabrication Process

Niobium alloy C-103 has high melting point. Fabrication process involves C-103 ingots production process and mechanical process. Niobium hafnium alloy is processed into ingots by combining electron-beam cast with vacuum consumable electrode arc furnace. Then C-103 is extruded or forged over 1200℃. After rolling and drawing under 500℃, niobium hafnium alloy C-103 is manufactured into sheets, strips, rods, wire or other fittings.

Niobium C-103 Welding

Niobium alloy C-103 has good weldability. The welding methods include argon tungsten-arc welding and electron-beam fusion welding. Welding quality depends on the purity of argon and vacuum. The purer the argon and the lower remaining pressure is, the better the welding quality

will be.

| C-103 Chemical Composition Maximum Weight % (Except Where Otherwise Specified) | |||||||||

| Products | C | O | N | H | Hf | Ti | Zr | W | Ta |

| C-103 | 0.015 | 0.025 | 0.01 | 0.0015 | 9 - 11 | 0.7 - 1.3 | 0.7 | 0.5 | 0.500 |

| C-103 Physical Properties | |||||||

| Products | Composition | Density /g·cm-3 | Temperature /˚C | Coefficient of Line-expansion /10-6K-1 | Recrystallization Temperature /˚C | Anneal Temperature /˚C | Elongation Brittle Transition Temperature /˚C |

| C-103 | Nb-10Hf-1Ti-0.7Zr-0.1W-0.1Mo-0.05Ta | 8.86 | 2349 | 4.5 (1203˚C) | 1038 - 1316 | 871 | - 196 |

| Niobium Alloys C-103 Foil, Sheet, Strip and Plate Mechanical Property | |||

| Ultimate Tensile Strength, Min, Psi (MPa) | Yield Strength(0.2 % offset), Min,Psi (MPa) | Elongation In 1 In.(25 mm) Gage Length, Min, % | |

| Material 0.05 in. (1.3 mm) and thinner: | |||

| Room temperature | 56 000 (385) | 40 000 (275) | 20 |

| 2000 ± 25°F (1100 ± 15°C) | 21 000 (145) | 16 000 (110) | 20 |

| Material greater than 0.05 in. (1.3 mm) in thickness: | |||

| Room temperature | 54 000 (370) | 38 000 (260) | 20 |

| 2000 ± 25°F (1100 ± 15°C) | 21 000 (145) | 16 000 (110) | 20 |

| Niobium Alloys C-103 Rod Bar and Wire Mechanical Property | |||

| Ultimate Tensile Strength, Min, Psi (MPa) | Yield Strength(0.2 % offset), Min,Psi (MPa) | Elongation In 1 In.(25 mm) Gage Length, Min, % | |

| Material 0.050 in. (1.27 mm) and smaller in diameter: | |||

| Room temperature | 56 000 (385) | 40 000 (275) | 20 |

| 2000 ± 25°F (1100 ± 15°C) | 21 000 (145) | 16 000 (110) | 20 |

| Material 0.051 in. (1.30 mm) and larger in diameter: | |||

| Room temperature | 54 000 (370) | 38 000 (260) | 20 |

| 2000 ± 25°F (1100 ± 15°C) | 21 000 (145) | 16 000 (110) | 20 |

| C-103 High-temperature Properties | |||||||

| Products | Composition | Shape | Temperature/˚C | Tensile Strength/MPa | Temperature/˚C | Modulus of Elasticity | Break Strength/MPa |

| C-103 | 10Hf, 1Ti, 0.7Zr | Sheet | 1093 | 189.8 | - | 112 490 | - |