Glass was once seen as a luxury. The houses of wealthy families are marked with intricate decorations and clear glass.

This was indicative of the high cost of production and the limited knowledge of how to produce clear glass.

As with many expensive commodities, however, man's industrial achievements unleashed mass glass

production and made it available to a wide range of consumers. Electric glass furnaces are crucial to

this transformation.

Until the 1950s, most industrial-scale plate glass production was carried out using conventional coal

- or gas-fired stoves. Engineers who wanted to take advantage of the growing power to improve the

efficiency of the process eventually turned to molybdenum glass melting electrodes.Molybdenum's

inherent thermodynamic and electrical properties make it the preferred solution for glass melting

electrodes, and despite the emergence of timely alternatives such as platinum and tin oxide,

molybdenum remains the preferred material for glass electric furnace electrodes.

Why use molybdenum electrodes?

Molybdenum is a refractory metal with a melting point of 2620°C (4748°F) and electrical conductivity in the

range of 1.914x107σ. Molybdenum material not only has good electrical and thermal conductivity, but also

has excellent corrosion and creep resistance, making it an ideal material for electrodes used to withstand

high temperature and corrosive molten glass.The high purity of pure molybdenum ensures that the glass

production process is not affected by impurities, the color of the finished product is clear, does not contain

impurities, not only improve the yield, but also reduce the production cost.

For more corrosive melts, it is best to use a good quality molybdenum alloy rather than a pure metal,

as harsh refining agents (such as antimony oxide) can damage standard glass smelt electrodes.Adding

zirconium in small concentrations to molybdenum alloys significantly improves corrosion resistance and

enables glass manufacturers to tackle challenging industries such as fiberglass manufacturing and

photovoltaic production. Molybdenum alloys also offer greater engineering flexibility, providing furnace

designers with one of the highest materials that can be integrated into production in a variety of

configurations.

Molybdenum electrodes produce a wide variety of glass in daily life, but also in all aspects of

industrial scientific research, from water cups to food containers and tableware; From insulation

to Windows in homes,offices and vehicles; Electronic panels for displays and solar cells; And a wide

variety of industrial and scientific vessels.

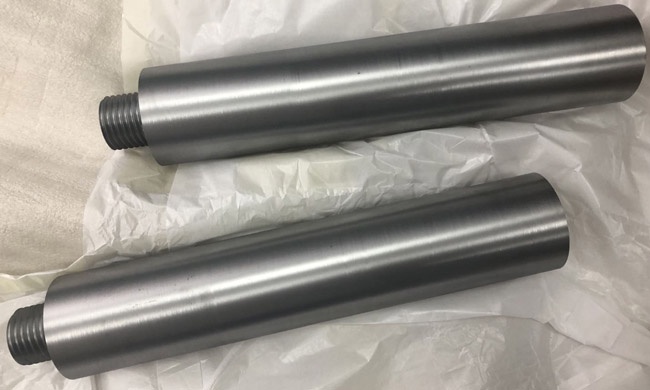

1. Dimensions and Tolerances

1.1 Diameter and production tolerances

Forged

Diameter [mm] Tolerance [mm] 30,0 - 50,0 ± 0,3 50,1 - 52,0 +0/-0,8 52,1 - 75,0 ± 0,4 75,1 - 120,0 ± 1,0 > 120,0 ± 1,5

Mechanical machined (Ground / Turned)

Diameter [mm] Tolerance [mm]

30,0 - 49,9 ± 0,3

50,0 - 165,0 ± 0,4

1.2 Straightness Diameter [mm] Straightness/meter [mm] Forged Ground / Turned 30,0 - 165,0 < 1,5 < 1,0

1.3 Guaranteed length tolerances

Diameter [mm] Length Tolerance 30,0 - 165,0 < 1000 mm ± 5 %

> 1000 mm ± 50 mm

1.4 Typical production lengths

Diameter [mm] Typical production length [mm]

30,0 -120,0 2000

120,1 -165,0 1500

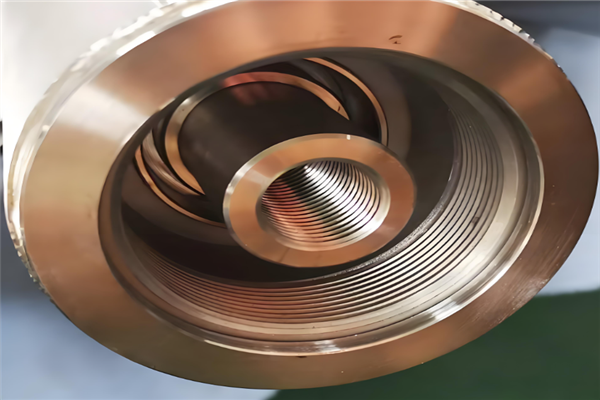

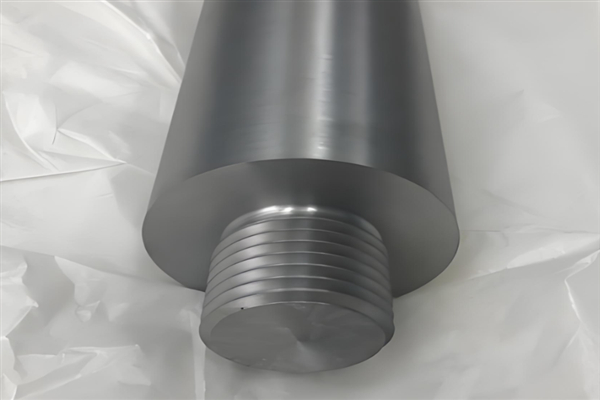

1.5 Threading

Upon request, the glass melting electrodes can be supplied with male or female threads at one or both ends.

Standard dimensions available (glass melting electrodes with recommended standard threads – further dimensions upon request)

Ø Ø-tolerance Surface Recommended standard threads

[mm] [mm] [mm] [mm] [inch]

31,75 ± 0,3 forged M22 x 1,5 M18 x 1,5 7/8 - 14 UNF

48 ± 0,3 forged M24 x 1,5 M22 x 1,5 7/8 - 14 UNF

50,8 +0/- 0,8 forged M27 x 3 M24 x 1,5 1 ¼ - 12 UNF

54 ± 0,4 forged M36 x 3 M27 x 3 1 ¼ - 12 UNF

60 ± 0,4 forged M36 x 3 M27 x 3 1 ¼ - 12 UNF

63,5 ± 0,4 forged M36 x 3 1 ¼ - 12 UNF

66 ± 0,4 forged M36 x 3 1 ¼ - 12 UNF

70 ± 0,4 forged M42 x 3 1 ½ - 12 UNF

76,2 ± 1,0 forged M42 x 3 1 ½ - 12 UNF

80 ± 1,0 forged M42 x 3 1 ½ - 12 UNF

90 ± 1,0 forged M58 x 3 2 ¼ - 8 UN

101,2 ± 1,0 forged M58 x 3 2 ¼ - 8 UN