1、 Measurements and tolerances

Unit:mm

Thickness | Max diameter |

2.0±0.1 | 660±0.2 |

1.0±0.08 | 660±0.2 |

0.5±0.04 | 660±0.2 |

0.3±0.03 | 660±0.2 |

Special sizes can be manufactured based on customers' requirements

2、 Physical and chemical properties

Purity:Mo≥99.95%;99.97%

W ≥99.95%;

Density:Mo≥10.2g/cm3 ;

W ≥19.3g/cm3;

Application temperature environment:≤2300℃;

3 、Manufacture process and equipment

Item | Process | Equipment | Quality check point |

1 | Mo sheet or W sheet | 1 Physical and chemical properties | |

2 | Check | 2 Measurements (length, width, and thickness ) 3 Surface quality | |

3 | Wire cutting | Wire cutting machine | 1 Surface clearness |

4 | Machining | CNC milling machine | 2 Tolerance according to drawing |

5 | Clean | Bending machine | 3 No pollutant on surface, and no crack |

6 | Check | Drilling press, Lathe | |

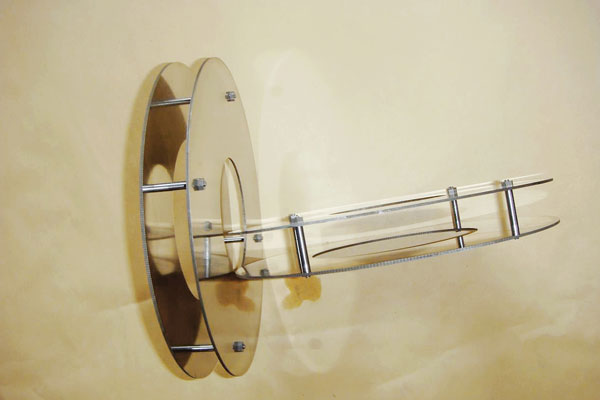

7 | Assembly | Assembly platform | 1 Surface clearness |

8 | Clean | 2 Solid structure and no loose | |

9 | Check | 3 Assembly tolerance | |

10 | Package | 4 Show certificate of quality |

4、 Application

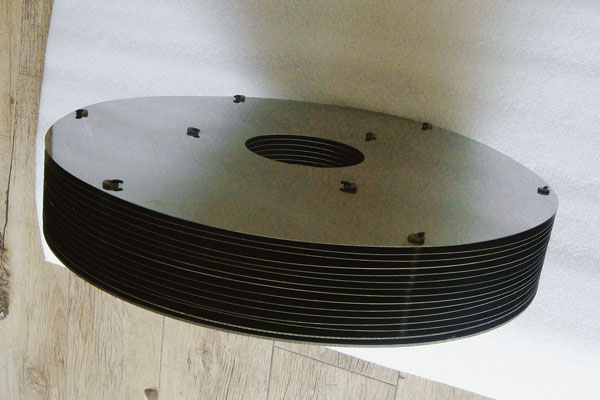

As the heat-shield parts in the sapphire growth furnace, the most decisive function of upper and bottom cover plate is to prevent and reflect the heat in the furnace. Heat-shield parts with high-density, exact-

measurement, smooth-surface, convenient-assembly and reasonable-design has great significance in improving the crystal-pulling。