In the semiconductor industry, high-purity graphite is mainly used as a heating system, insulation cover, electrode, etc. The use of high-purity graphite for these parts also makes full use of the high-purity graphite's high temperature resistance. The advantages of high-purity graphite, such as corrosion resistance, oxidation resistance, and electrical and thermal conductivity, are applied to the semiconductor industry, making the work piece longer life, more wear-reducing and power-saving. Our company uses German semiconductor grade graphite materials to precisely manufacture graphite consumables for ion implantation, providing standard parts and customized specifications.

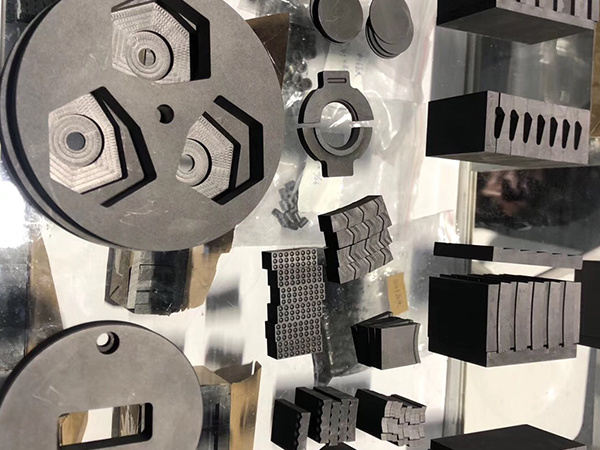

High-purity graphite can be used as a low atomic number material according to the characteristics of uniform and fine particles. It has strong bombardment resistance to ions and plasmas, strong corrosion resistance, high purity, no metal ions, no pollution to semiconductors, and metal parts exposed In the ion implantation equipment will cause high loss, so use the corresponding graphite parts as the shield. For plasma cvd parts, plasma vcd susceptor, electrode chamber, nozzle, lining, sputtering electrode, movcd susceptor, etc.

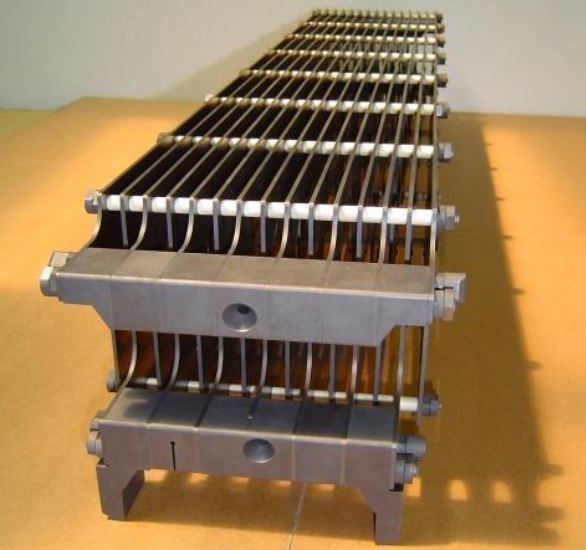

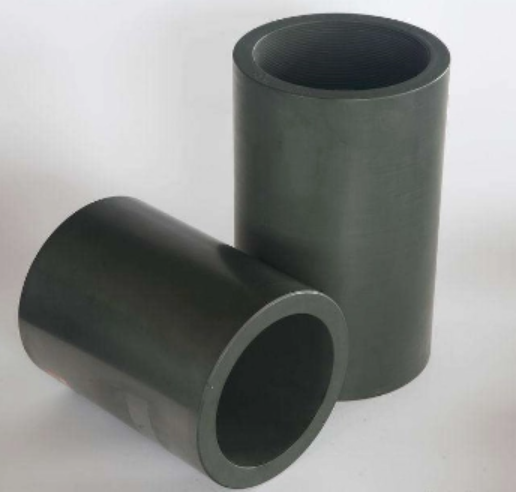

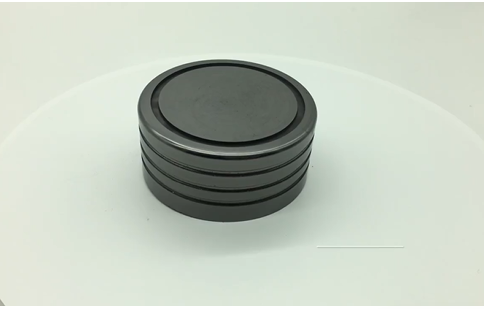

The graphite parts used in the Czochralski single crystal furnace are a kind of consumable parts, which are processed from various high-purity graphites. For example, the graphite crucible and other graphite parts adopt high-purity fine-grain structure graphite; the graphite heater adopts high-purity isotropic graphite; the graphite insulation cover and graphite cover plate adopt high-purity medium-grain structure graphite.

Properties of Isostatic pressing graphite

Project | Unit | Technology value | Technology value |

Density | g/cm3 | ≥1.8 | ≥1.85 |

Compressive strength | Mpa | 85 | 90 |

Flexural strength | Mpa | 40 | 45 |

Resistivity | μΩm | 11-13 | 11-13 |

Shore hardness | -- | 55 | 60 |

Ash content | ppm | 50-500 | 50-500 |

coefficient of thermal expansion | 10m-6/℃ | 4.1 | 4.3 |

The average particle size | μm | 22 | 22 |